Eye and face injuries are among the most common, yet most preventable, injuries occurring in the workplace. Each day, approximately 2,000 U.S. workers experience eye injuries severe enough to require medical attention. These incidents not only result in personal injury but can also lead to diminished or lost productivity, costs for medical treatments, and unnecessary insurance claims.

Here’s a surprising statistic: The National Institute for Occupational Safety and Health (NIOSH) reports that up to 90% of eye injuries at work could be prevented through proper protective eyewear.

Effective eye and face protection does more than keep your company and employees in regulatory compliance. Using the correct protective gear can protect vision, reduce lost workdays, lower healthcare costs, and maintain steady productivity. Most importantly, it helps make sure your employees stay safe on the job.

Understanding the Risks

Workers in various fields, from construction sites and manufacturing plants to laboratories and healthcare settings, face multiple eye and face hazards. Flying debris such as metal fragments, wood chips, and particles are a significant risk, particularly in manufacturing and construction. Chemical splashes, harmful ultraviolet (UV) and infrared radiation from welding or lasers, and biohazard exposure in medical settings, fabrication, and anywhere else they are used.

Despite readily available protective gear, injuries often occur due to inadequate awareness, improper PPE selection, or simply not wearing protection consistently. Workers may underestimate the danger of certain tasks or rely on inappropriate equipment, leading to preventable incidents.

Eye Safety Standards You Should Know

To address these risks, OSHA outlines clear regulations under standards 29 CFR 1910.133 (general industry) and 1926.102 (construction). Employers must not only provide eye protection but ensure it meets the stringent American National Standards Institute (ANSI) Z87.1 specifications.

The ANSI Z87.1 standard outlines critical performance criteria, including impact resistance, chemical protection, and UV radiation shielding. PPE marked with “Z87+” indicates high-impact resistance, essential for jobs involving flying objects. Labels such as D3 (liquid splash), D4/D5 (dust), U6 (UV protection), and W (welding filter shades) guide users in choosing appropriate gear for specific hazards. Compliance with these standards ensures reliable performance and protection in critical situations.

Choosing the Right PPE for Eye Protection

Selecting protective equipment isn’t as simple as grabbing any pair of safety glasses. Effective protection requires matching PPE specifically to the hazards of the task:

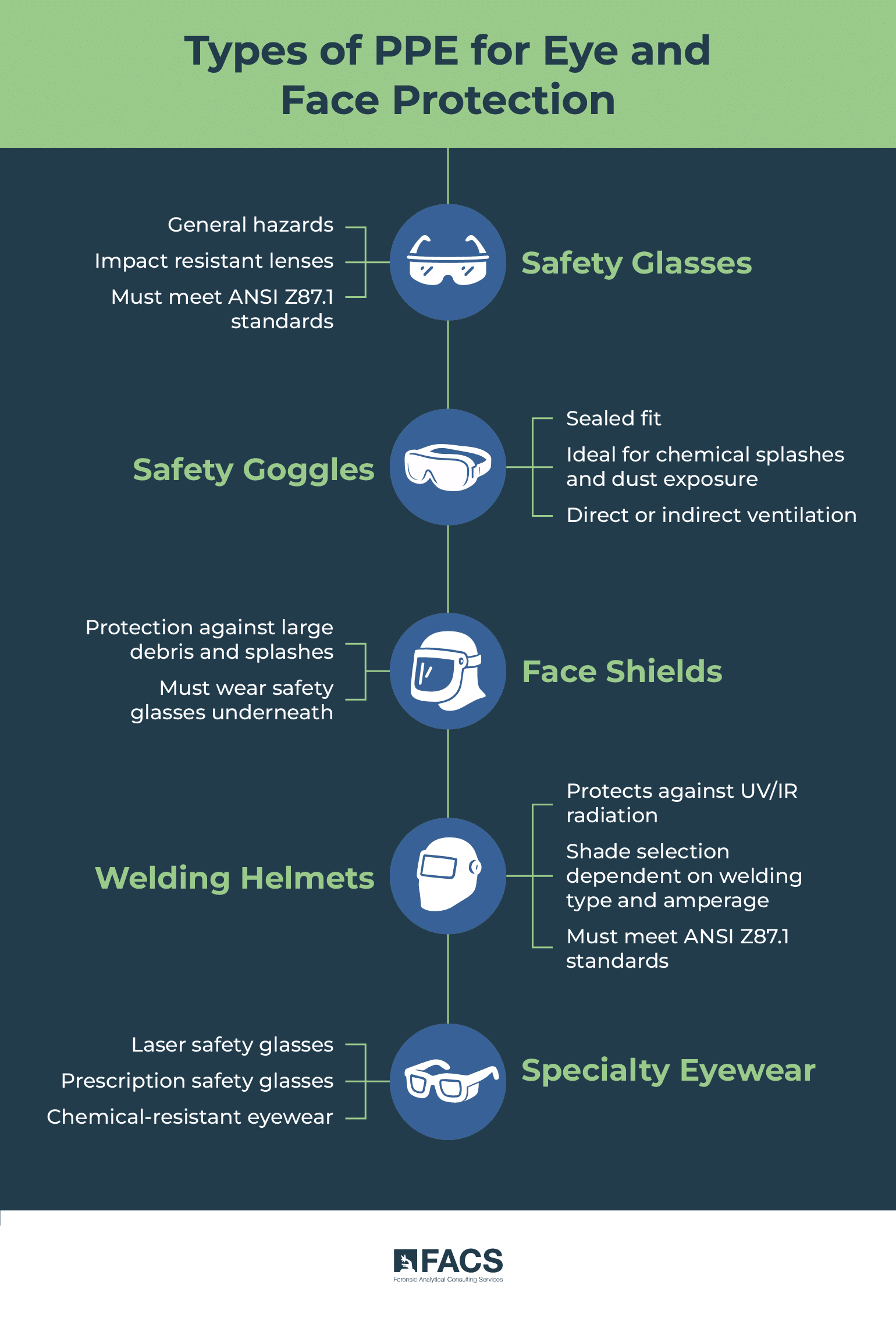

- Safety Glasses: Suitable for general impact hazards, must meet Z87.1 standards.

- Safety Goggles: Provide sealed protection from chemical splashes and dust. Look for ventilation types based on your exposure (direct, indirect, or non-vented).

- Face Shields: Offer extra protection from larger debris or chemical splashes but always require safety glasses or goggles underneath.

- Welding Helmets: Essential for protection against intense UV and IR radiation; ensure compliance with ANSI standards and proper shade selection.

- Specialty Eyewear: Laser protection, chemical-resistant, and prescription eyewear provide specialized safety where general eyewear might fall short.

Comfort and proper fit significantly influence compliance. Workers are far more likely to consistently wear comfortable PPE. Regularly involving workers in the selection process helps ensure the equipment meets their comfort and functional needs, thereby promoting consistent use.

Common Eye Protection Mistakes and How to Avoid Them

Employers and employees share responsibility for workplace safety. Common errors include using incorrect PPE for tasks, wearing damaged equipment, prematurely removing gear, or simply neglecting to wear it at all.

One frequent mistake is choosing inadequate PPE, such as opting for safety glasses when goggles or a face shield are required. Workers sometimes underestimate hazards, believing basic protection is sufficient, which can lead to serious injuries. Employers must conduct thorough hazard assessments and clearly communicate the specific PPE requirements for each task.

Damaged or worn-out PPE is another common issue. Scratched lenses, broken straps, or missing side shields drastically reduce protection and visibility. Regular inspections should be part of daily routines, with damaged PPE immediately replaced. Employees must be trained to recognize signs of wear and encouraged to report issues without hesitation.

Premature removal of protective gear is a significant risk. Workers may remove goggles or shields when they feel safe, even though hazards are still present. Employers should consistently reinforce that PPE must remain worn until employees are fully clear of all risks.

Another critical mistake is inadequate maintenance and storage of PPE. Dirty or improperly stored gear can impair visibility and reduce protection. Establish clear protocols for cleaning, maintaining, and storing PPE correctly. Easy access to well-maintained equipment encourages consistent and proper use.

Neglecting comprehensive training is also problematic. Employees must fully understand the proper use, fit, and limitations of their PPE. Regular training sessions reinforce safety protocols and provide opportunities to address concerns or misunderstandings.

Finally, poor enforcement and lack of leadership examples can undermine compliance. Managers and supervisors must visibly support and enforce PPE protocols consistently, setting the standard by correctly using their own equipment.

Emergency Preparedness and Workplace Safety

Even with precautions, accidents can happen, emphasizing the critical role of emergency equipment. ANSI Z358.1 standards guide the proper installation and use of eyewash stations and emergency showers, which should always be accessible “for quick drenching or flushing of the eyes and body.”

Proper training in emergency responses — such as immediately flushing chemical splashes for at least 15 minutes — can significantly reduce injury severity, preventing long-term vision impairment. Regular emergency drills and clearly marked equipment locations ensure rapid and effective responses during real incidents.

Building a Culture of Safety at Work

Safety awareness is a cultural commitment. Leadership must actively prioritize and demonstrate safe working behaviors. Regular inspections, ongoing training, and recognition programs encourage everyone to participate and reinforce safe practices.

Strong safety cultures don’t develop by chance. They require consistent commitment, clear communication, and collaborative effort between employers and workers. Encouraging employee feedback and active participation fosters an environment where safety becomes ingrained as a core value at your company.

Emerging Trends and Future Innovations

New PPE innovations continue to emerge, including ergonomic designs, advanced materials, and smart technology like augmented reality (AR-enabled) glasses and sensors that detect hazards in real-time. These innovations promise enhanced protection, comfort, and usability, driving greater compliance and safety.

However, adopting new technologies always requires thorough risk assessments to ensure they don’t exacerbate hazards instead of lessening the threat. Staying informed and adaptable helps organizations continually improve their safety strategies.

Eye and face protection is fundamentally about safeguarding health, livelihoods, and lives. With appropriate awareness, thorough hazard assessments, and proactive use of PPE, workplaces can significantly reduce the risk of preventable injuries. Every person on your team should be encouraged to work safely, shown how to work safely, and provided the equipment that can help them work safely.

For more information, see the FACS/Bullard presentation on eye and face protection or contact FACS directly at (888) 711-9998.