The new Cal/OSHA indoor heat regulation for California workplaces is now in effect. Understanding its requirements can help keep your company in compliance and protect the health of your workers.

For many industries, from construction to manufacturing, these rules represent a significant shift in how indoor heat risks are regulated and managed.

This article will guide you through the essentials of the regulation: when it applies, what’s required, and practical steps to implement a compliant heat illness prevention program.

Are You Exempt From the Indoor Heat Regulation?

First, let’s make sure you’re in the right place. Understanding the new California indoor heat regulation does take time and effort — however, your operations may not be covered by it.

Here is a list of the exceptions to the new law:

- Teleworkers performing duties at a place of their choosing

- Incidental heat exposure (fewer than 15 minutes in any 60-minute period), except that working in vehicles without air conditioning and those working with shipping or intermodal containers while loading, unloading, or doing related work

- Emergency operations aimed at the protection of life or property

- Prisons, local detention facilities, or juvenile facilities

- Outdoor workplaces (although this is covered by Cal/OSHA’s outdoor heat regulation)

None of the exceptions mean that working in the heat doesn’t matter, only that there is a personal responsibility to protect oneself or there are already regulations in place that govern work where indoor heat may be a health concern.

When Does the Indoor Heat Regulation Apply?

The new indoor heat regulation for workplaces in California outlines specific situations that require you to safeguard employees working in elevated temperatures.

When are the requirements of the regulation triggered?

The regulation triggers at 82 degrees Fahrenheit (F) for workers wearing garments that restrict heat removal from their bodies (wearing work coveralls, gloves, or helmets, for example) and for workers working in a high radiant heat environment. If those conditions are not in existence, the trigger point is 87°F.

What is an “indoor space”?

Indoor space is defined as a space that is under a ceiling or overhead covering that restricts airflow and is enclosed along its entire perimeter by walls, doors, windows, dividers, or other physical barriers that restrict airflow (whether those barriers are open or closed). During building construction, a workplace becomes “indoor” once the barriers are in place. Note that the outdoor exception for shaded spaces does not apply indoors.

What Must You Do to Comply With the New Indoor Heat Regulation?

Once conditions trigger the new regulation, employers are required to do the following:

Employers must provide potable drinking water

- Employers must ensure that employees have no cost access to potable, cool drinking water.

- Each worker should have at least one quart of water per hour available during their shift.

- Water must be placed near work areas and cool-down locations. Workers should not have to travel long distances to access it.

- While you don’t need to provide all the water at the start of the shift, it must be replenished regularly to meet the hourly requirement.

Employers must provide access to cool-down areas

- Provide access when indoor temperatures reach 82°F or higher, you are required to provide a designated cool-down area where employees can rest and recover.

- These areas must be shielded from radiant heat and maintained at temperatures below 82°F.

- Employees should be encouraged to use cool-down areas regularly, and any worker who requests a cool-down rest period should be allowed one.

Employers must monitor heat levels and record data

- Begin monitoring temperature and heat index when indoor temperatures reach 82°F. Additional measurements should be taken whenever temperatures are expected to rise by 10°F or more.

- Employers must record the measured temperature or heat index (whichever is higher) and retain those records for at least 12 months. Best practice is to integrate this documentation into your regular project files.

- Instruments used for measuring must be maintained per the manufacturer’s instructions.

- Instruments used must provide the same results as indicated by heat index charts from the National Weather Service for temperature at certain humidity levels.

The new indoor heat regulation for California also requires a written implementation plan and training for both workers and supervisors. You’ll find more about those in the content below.

Invest in Reliable Monitoring Tools

Measuring and tracking workplace conditions is critical for maintaining compliance with the new California indoor heat regulation and ensuring employee safety. Make sure the tools you use for monitoring are accurate and simple to use. Be sure to train management on their proper operation.

- Thermometers: Keep trustworthy thermometers on the worksite to monitor temperature.

- National Weather Service Heat Index Chart: Readily accessible online. Print and laminate for regular use. The chart provides the heat index at the temperature and humidity levels you have recorded.

- Wet Bulb Globe Thermometers: These devices measure temperature, humidity, air movement, and radiant heat. They are ideal monitoring instruments, especially in manufacturing or other enclosed spaces.

- Personal Heat Stress Monitors: These are worn by selected employees to provide information for that specific person.

- Heat Stress Apps: The American Industrial Hygiene Association’s heat stress app can help you assess conditions, review precautions, and access real-time heat index forecasts. The app also provides risk factors, training recommendations, and programmable hydration and rest reminders.

Remember: The regulation is triggered by either the current temperature or current heat index. At higher relative humidity levels, the heat index can be greater than 82 °F while the temperature is under 82 °F.

Control Measures for Managing Indoor Heat

Compliance with the indoor heat regulation requires a layered approach to managing heat exposure. By combining engineering, administrative, and personal protective measures, you can create a safer environment for your team while meeting regulatory standards.

Engineering Controls: Reducing Heat at the Source

The first line of defense against indoor heat is to reduce temperatures and maintain a safe environment using engineering controls. These measures focus on modifying the work environment itself:

Key factors to assess include:

- Temperature Control Systems: Install or maintain air conditioning units, fans, and ventilation systems to keep temperatures below 87°F — or below 82°F in areas where employees wear restrictive clothing or radiant heat is present in the work area.

- Radiant Heat Barriers: Use shielding materials or insulation to block heat from equipment, machinery, or sunlight.

- Humidity Reduction: Dehumidifiers or improved ventilation can lower humidity levels, making the work environment more comfortable and safer for employees.

Administrative Controls: Scheduling and Breaks

When engineering controls alone aren’t enough or aren’t feasible, administrative practices can further mitigate heat risks:

- Work-Rest Cycles: Adjust workloads and schedules to allow for regular rest breaks in cool-down areas.

- Staggered Shifts: Where possible, schedule physically demanding tasks during cooler parts of the day.

- Job Rotation: Rotate employees between high-heat tasks and less strenuous roles to prevent prolonged exposure.

Personal Protective Equipment (PPE): When Other Measures Still Aren’t Sufficient

In some cases, PPE can provide additional protection against heat-related risks:

- Cooling Vests and Wraps: Wearable items that help maintain lower body temperatures during extended work periods.

- Moisture-Wicking Clothing: Lightweight, breathable materials can aid sweat evaporation and heat dissipation.

- Specialized Headgear: Helmets with built-in cooling pads or ventilation improve comfort and safety.

While PPE can be a helpful supplement, it should never replace engineering or administrative controls. Instead, it serves as a last line of defense in situations where other measures cannot fully address the risks.

How Is Heat Illness Detected?

Heat illness can present itself in several ways, ranging from mild discomfort to severe medical emergencies. Train your team to recognize these symptoms and respond both quickly and appropriately.

- Heat Rash: Small red bumps or clusters, often on the neck, chest, groin, or underarms. Common in humid environments where sweat can’t evaporate.

- Heat Cramps: Painful muscle spasms caused by dehydration and salt loss. Often a warning sign of more serious heat stress.

- Heat Syncope: Fainting for a short duration, dizziness, and light-headedness can signal a developing problem.

- Heat Exhaustion: Symptoms include heavy sweating, dizziness, nausea, weakness, and a rapid pulse. Employees in this state need immediate cooling and hydration.

- Heat Stroke: The most serious form of heat illness. Symptoms include hot, dry skin, confusion, and loss of consciousness. Heat stroke requires emergency medical attention and is fatal in 50% of cases if untreated.

Emergency Procedures: Responding to Heat Illness

Even with the best prevention strategies, heat illness can occur. Having a clear and effective emergency response plan is not only a regulatory requirement but also a critical element in protecting your employees from severe outcomes.

You must have first aid supplies available, access to Eemergency Medical Services (EMS) , and a way to communicate with EMS and with your crew. Someone must be available to call 911 and provide clear directions to the site.

Make sure EMS access is not restricted at the site or that someone can meet the responders at the gate or barrier to provide entry. Remember that cellular phones are not reliable in some areas, meaning you must provide an alternate method for communications.

Immediate Actions for Heat Illness Symptoms

Recognizing heat illness early can prevent it from escalating. When symptoms do appear, take immediate action. Never leave the employee alone and do not send a worker home without offering medical assistance.

Here’s how to Prepare:

Heat Illness Prevention

Acclimatization: A Key Step in Prevention

New or returning workers are most at risk during their first 14 days on the job. The same applies to workers assigned to a new geographical area. Gradually introducing employees to high-heat environments is essential. Nearly 75 percent of illness fatalities occur during the first week of working in excessive heat environments.

- Follow the 20% rule. Start new workers at 20% of their full workload on day one, increasing by 20% each day as they acclimate.

- Sudden temperature increases can affect even seasoned employees. Keep a close eye on conditions and adjust workloads, as needed.

- Heat waves are defined as temperatures at least 10°F greater than the average high daily outdoor temperature for the preceding five days and are at least 80°F. Make sure to document your daily temperature recordings.

Encourage Team Awareness

One of the biggest dangers of heat illness is that workers may not recognize the symptoms themselves when they are affected.

Emphasize the importance of the following safeguards:

- Looking Out for One Another: Supervisors and coworkers should monitor each other for signs of heat stress.

- Reporting Symptoms Early: Employees must feel comfortable reporting any signs of heat illness without fear of repercussions.

By fostering a culture of awareness and prevention, you reduce risks and reinforce your commitment to safety. With these foundational steps, your team is better prepared to avoid the dangers of heat illness altogether.

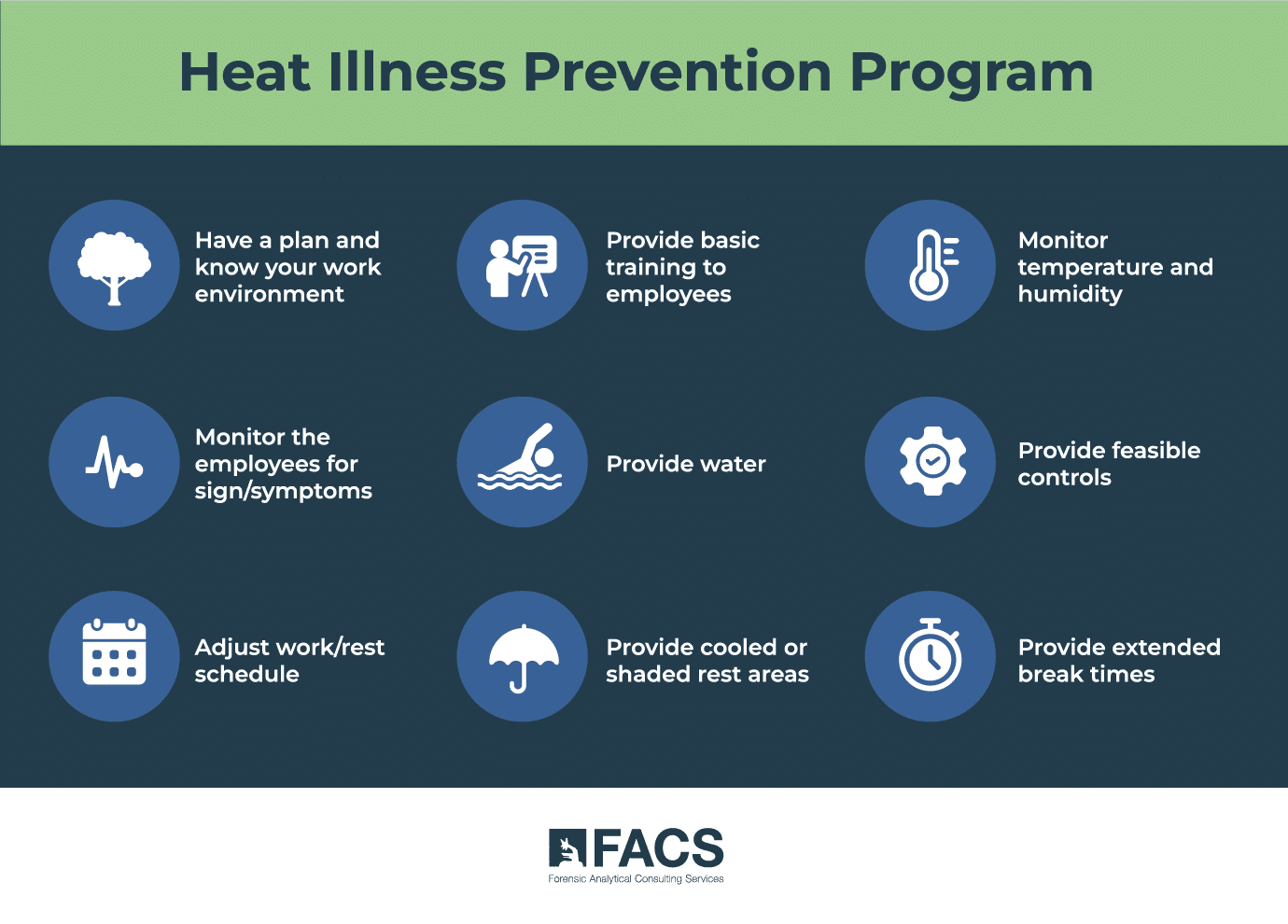

Training and Compliance Programs for Heat Illness Prevention

Effective training is the cornerstone of compliance with California’s indoor heat regulation. Both employees and supervisors need to understand the risks, recognize symptoms, and know how to respond to heat-related illnesses. Developing a robust training program and a comprehensive heat illness prevention plan ensures everyone is prepared to stay safe and meet regulatory standards.

Employees must receive training on the following key topics:

- Environmental risks such as high temperatures and humidity

- Personal risks such as dehydration, inadequate acclimatization, and restrictive clothing

- The added burden of heat load from exertion, work clothing, and other factors

- Site-specific protocols for reporting symptoms and summoning medical help

- The importance of adequate water intake

- The importance of acclimatization

- Recognizing heat illness symptoms and first aid procedures

- Emphasis on never leaving a distressed employee alone and reporting any observed issues

- EMS procedures for the worksite

Supervisors must receive training on the following topics:

Supervisors require more detailed training to effectively oversee heat illness prevention and response efforts:

- Supervisors must understand every aspect of the training employees receive

- How to follow the requirements of the regulations and your stated procedures to ensure employees receive timely and appropriate medical attention

- Full knowledge of EMS procedures and clear communication during emergencies

- How to measure temperature, humidity, and heat index using approved tools or apps.

- Proper recordkeeping procedures, including what data to document and how long to retain it

Develop a Heat Illness Prevention Plan

You must have a written plan for establishing, implementing, and maintaining your health illness prevention program. It should be specific to your worksite and address all aspects of indoor heat management, including the following:

- How drinking water will be supplied, monitored, and replenished

- Cool-down area locations and maintenance procedures

- Guidelines for adjusting workloads and break times based on temperature conditions

- Steps for identifying and responding to heat illness

- How to summon medical help and guide EMS responders to the worksite

- How and when employees and supervisors will be trained

- A description of the feasible control measures you will implement as needed

Ongoing Compliance and Resources

Maintaining compliance isn’t a one-time effort. Make training and plan updates part of your regular safety routine:

- Provide annual updates or as regulations change

- Adapt your heat illness prevention plan as your worksite or operations evolve

- Utilize tools like the Cal/OSHA website and industry-specific guidance to stay informed

By understanding the new regulation, providing the necessary resources, and building a culture of safety awareness, you can reduce risks and help ensure your workers stay safe and productive

Contact FACS online: Ask FACS