2,000 years ago lead was used for piping water, minting coins, as an ingredient in cosmetics, to sweeten wines, and for many other things. Lead is malleable, durable, and abundant — all valuable properties for many products still produced today.

Unfortunately, lead is also toxic to humans.

The Roman architect, Vitruvius, warned about the negative health effects of lead in the first century BCE. Mining with lead, working with lead, drinking water from lead pipes — Vitruvius said all are hazardous and that clay is much preferred for potable sources of water. It took hundreds of years before those warnings were taken seriously.

Lead Standards and Regulations in the USA

One of the earliest regulations in the United States was the Lead-Based Paint Poisoning Prevention Act of 1971. This act marked the beginning of federal efforts to address lead hazards, particularly in housing. It aimed to reduce lead poisoning in children by prohibiting the use of lead-based paint in residential structures that received federal funding.

The Environmental Protection Agency (EPA) took further steps by phasing out leaded gasoline starting in the mid-1970s, with a complete ban effective by 1996 that dramatically reduced airborne lead levels. Additionally, in 1978, the Consumer Product Safety Commission (CPSC) banned the use of lead-based paint, defined as paint containing 0.5% or 5,000 parts per million lead, in residential properties and on products intended for children, citing the toxicity of lead and the risk of lead poisoning.

These actions laid the groundwork for subsequent regulations and efforts to mitigate lead exposure and protect human beings. They reflected a growing awareness of lead’s health implications and a commitment to environmental and public health safety.

Is Lead Still a Health Hazard?

Lead is a naturally occurring element that has been linked to a range of serious health issues, from cognitive impairment and developmental delays in children to cardiovascular problems in adults. It is now understood that there is no safe level of lead exposure to lead for children. Regulatory agencies are tightening restrictions at every juncture on lead’s path from the mining phase to the disposal phase.

Given the abundance of evidence about lead’s toxicity, people are often surprised that lead is still used in various applications — including paint, batteries, shielding for radiation, and certain types of glass and ceramics. Residential paint can still contain up to 90 parts per million lead and “lead free” plumbing fixtures can contain small amounts of lead used to make brass. Efforts to minimize exposure reflect a balance between utilizing lead’s beneficial properties and mitigating its health risks.

The FACS webinar update on lead standards highlighted a staggering finding from a study conducted by Duke and Florida State University: As much as half of the US population born before 1996 may have had significant lead exposure, resulting in approximately 824 million lost IQ points. This underscores the critical need for rigorous standards and protections to mitigate lead exposure.

Changes to Lead Standards

Regulatory changes are not just bureaucratic whims but are informed by a deepening scientific consensus on the dangers of lead. Federal and state agencies are uniformly mobilizing to update and tighten lead-related regulations.

Among the most significant proposed changes are those by the EPA which aim to lower the clearance and hazard levels for lead on surfaces and redefine what constitutes lead-based paint.

The city of Oakland, for example, implemented rules mandating permits for projects disturbing paint in older homes and childcare facilities. This and other regulations highlight a localized response to a nationwide health concern.

The Occupational Lead Poisoning Prevention Program under the California Department of Public Health (CDPH) is in the process of updating Title 17 and will bring the federal renovation, repair, and painting rule into the standards of California law.

Information found in the FACS lead standard updates webinar outlines the trajectory of regulatory evolution, from recognizing lead as a hazard to implementing stricter measures aimed at reducing exposure. These changes underscore a commitment to public health, driven by a blend of scientific evidence and regulatory innovation.

What Should Employers Do to Meet Updated Lead Standards?

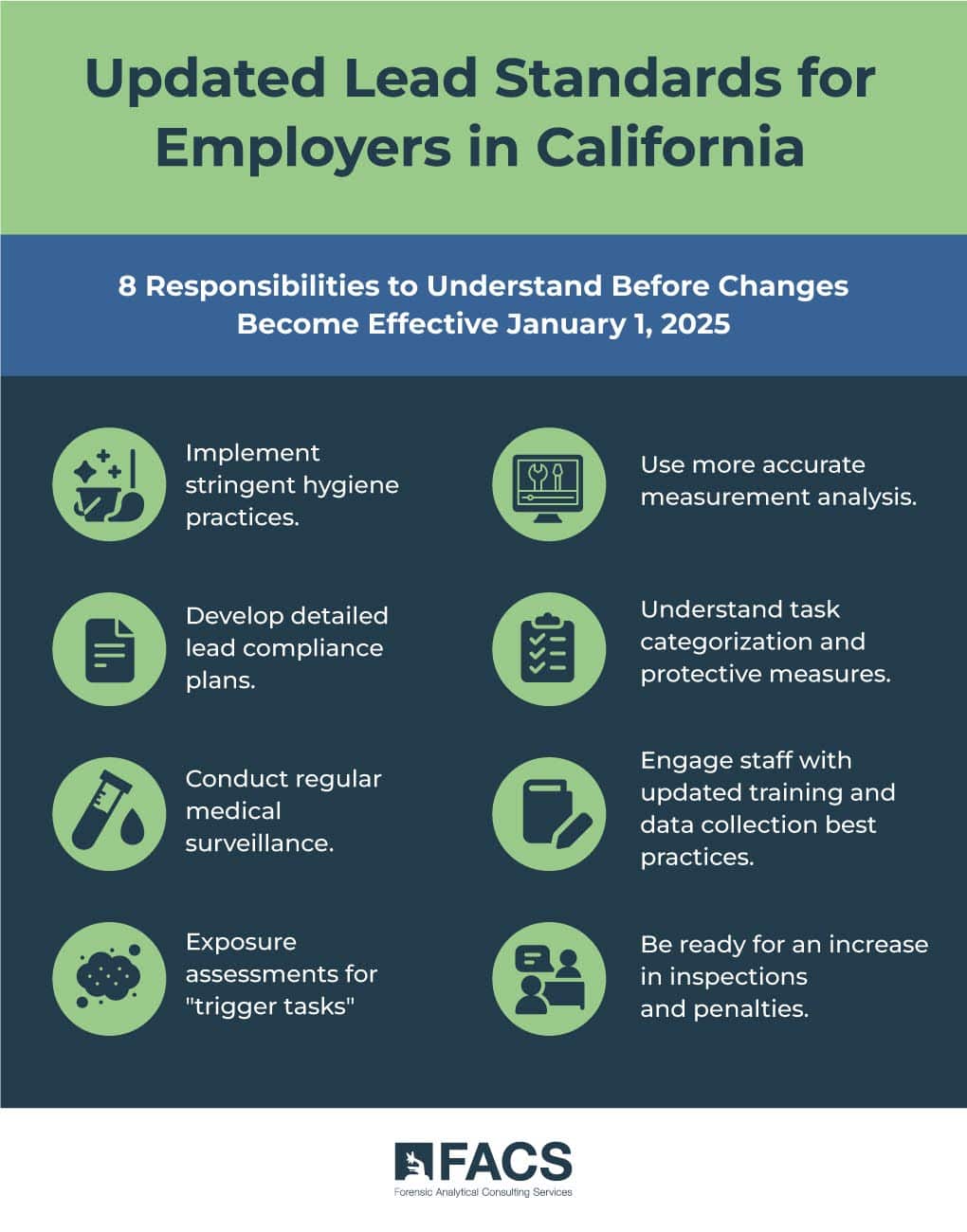

Cal/OSHA has updated their construction and general industry standards for lead, effective as of January 1, 2025. The sweeping updates to lead regulations present a complex challenge for employers, especially in the construction industry. These challenges are not merely administrative but involve a comprehensive overhaul of workplace practices to ensure the safety and health of employees.

Employers are tasked with instituting stringent hygiene practices, developing detailed lead compliance plans, and conducting regular medical surveillance, even for tasks that involve what was historically considered minimal lead exposure. The introduction of more accurate measurement analysis and the requirements for “trigger tasks” introduce additional layers of complexity and potential costs.

Furthermore, the nuanced nature of the new regulations demands a high level of vigilance from employers to stay compliant, particularly in understanding the categorization of tasks and the specific protective measures required for each level of exposure. Employers should not only adapt to these regulations but also proactively engage in training and data collection to preemptively address compliance requirements.

How Will the New Lead Standards Be Enforced?

The effectiveness of these regulatory updates hinges on robust enforcement mechanisms, and that raises concerns about compliance and oversight.

The uncertainty surrounding the enforcement of the new standard is palpable among employers, given the historical challenges associated with regulatory compliance in the construction sector. The potential for increased inspections and penalties for non-compliance add to the apprehension.

The webinar underscored the importance of employers gathering data and establishing a baseline for future assessments to navigate the uncertainties of enforcement. The anticipation of more stringent enforcement efforts by Cal/OSHA, possibly through the hiring of additional inspectors, reflects a broader commitment to safeguarding workplace health. This dual focus on compliance and enforcement embodies the evolving landscape of occupational safety amid the persistent challenge of lead exposure.

Occupational Lead Exposure and the Path Forward

The landscape of lead regulation is undergoing a pivotal transformation, driven by a confluence of scientific insight, public health advocacy, and regulatory focus. The updates to lead standards, while presenting formidable challenges for employers, underscore a collective endeavor to fortify worker safety and mitigate the health risks associated with lead exposure.

However, the journey does not end with the enactment of stricter regulations; it continues with diligent compliance, robust enforcement, and the unwavering commitment of all stakeholders to safeguard the well-being of workers and communities.

The lessons shared in the FACS lead standard updates webinar serve as both a blueprint and a call to action, emphasizing that the health impacts of lead exposure are preventable with informed, concerted efforts. Regulators are doing their part. It is incumbent upon employers to do theirs.

To speak with a FACS lead plan expert, call (888) 711-9998.